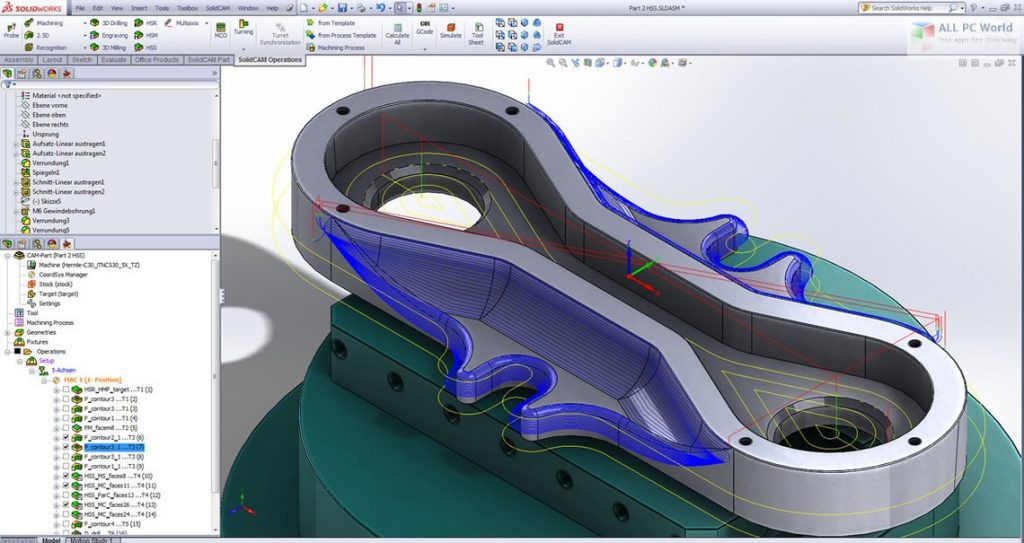

With SOLIDWORKS CAM, you will be able to enhance your manufacturing process by capturing company standards, speed up quoting, and test manufacturability of a design earlier in the process. Rules-based machining leverages tolerances that have been assigned to each component, allowing users to focus on the critical areas of making a part rather than touching every feature that needs to be machined. SOLIDWORKS CAM uses rules-based machining to enhance the programming process in the same way rules-based design helped to speed up the drawing and design process. Leveraging the SOLIDWORKS part and assembly interface enables you to easily and quickly learn SOLIDWORKS CAM and take advantage of rules-based machining with minimal effort. With the programming data stored inside the SOLIDWORKS part or assembly, you can easily manage files and references just like they do today. SOLIDWORKS CAM delivers an easy-to-use and fully functional programming experience based on 19 + years of development as a Gold Level Solution Partner. Leveraging the SOLIDWORKS part and assembly interface allows you to easily and quickly learn SOLIDWORKS CAM and take advantage of rules-based machining with minimal effort. These rules can then be automatically applied based on material type and geometry of the feature. The foundation of SOLIDWORKS CAM is rules-based machining, where you can teach the system what standard machining strategies are important to them. SOLIDWORKS CAM offers 3+2 machining as well as full support for configurations, parts, and assembly machining workflows. SOLIDWORKS CAM is a 2.5-axis milling and turning solution powered by CAMWorks®. Certified SOLIDWORKS Professional (CSWP).SOLIDWORKS Product Data Management (PDM).

0 kommentar(er)

0 kommentar(er)